|

|

#1 |

|

Участник

|

Sumit Potbhare: Different type of Staging Locations | Retail Warehouse Blueprint | Approach to D365 for Commerce with Adv WH Mgmt

Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

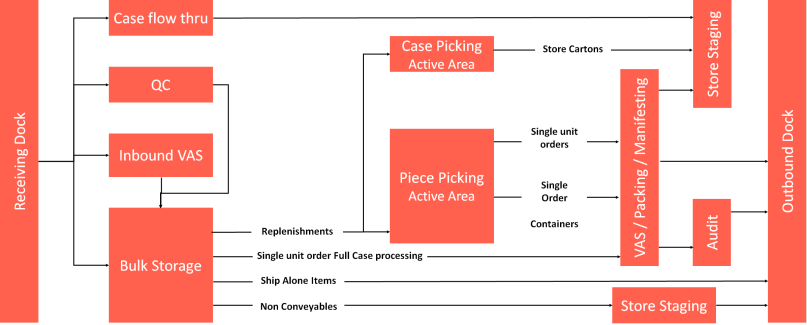

============== Hi Guys, I hope you have gone through my earlier post on the Retail Warehouse blueprint. An accurate Retail Warehouse layout can increase the efficiency of Warehouse processes and productivity of Warehouse workers. In this blog, we’re going to discuss the various types of Staging Locations that a Retail Warehouse needs, both at the inbound as well as the outbound side of the Warehouse layout design. Let us recall the Retail Warehouse blueprint that we saw in my previous post. It has multiple Staging locations –

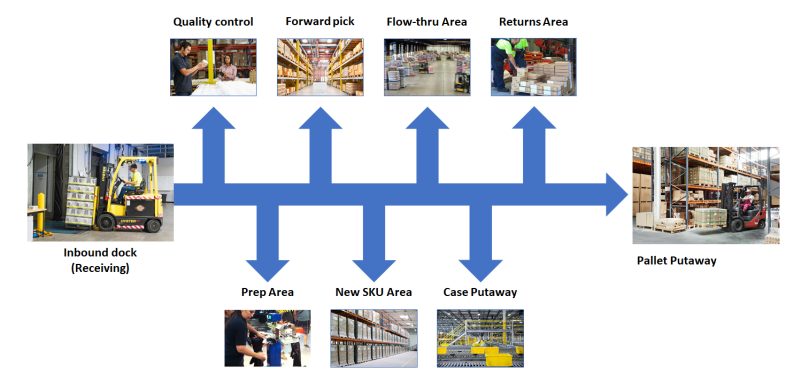

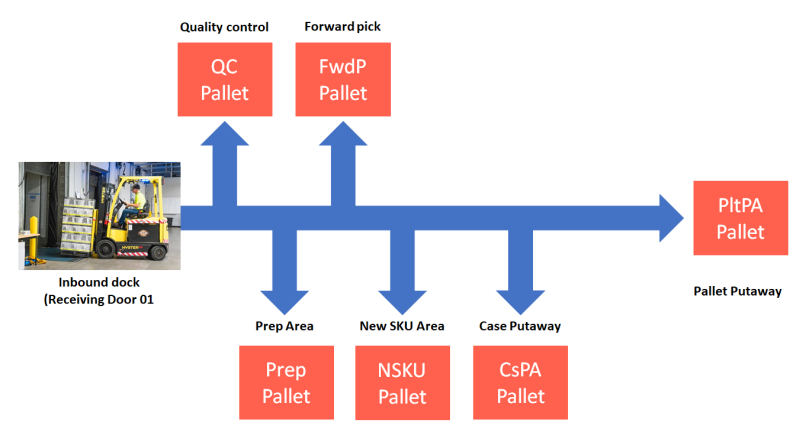

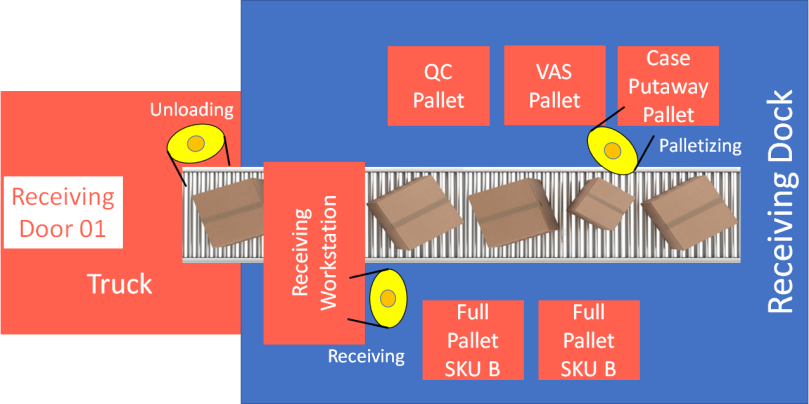

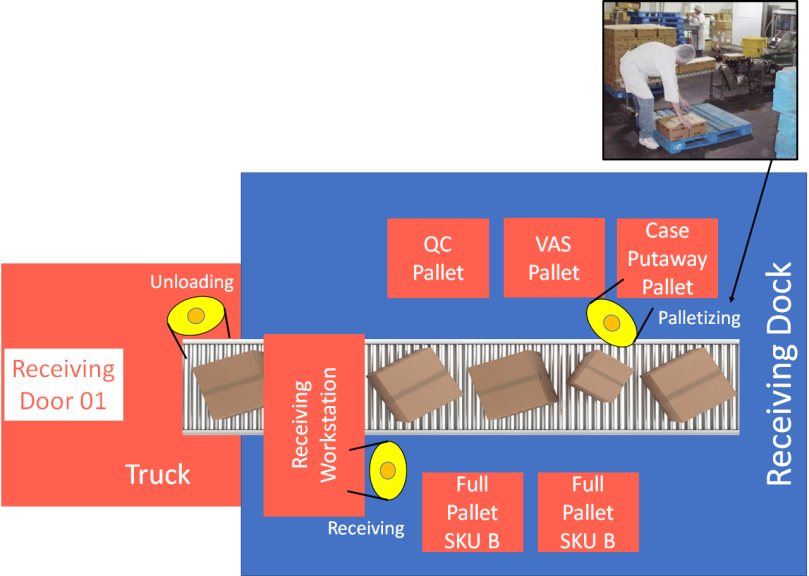

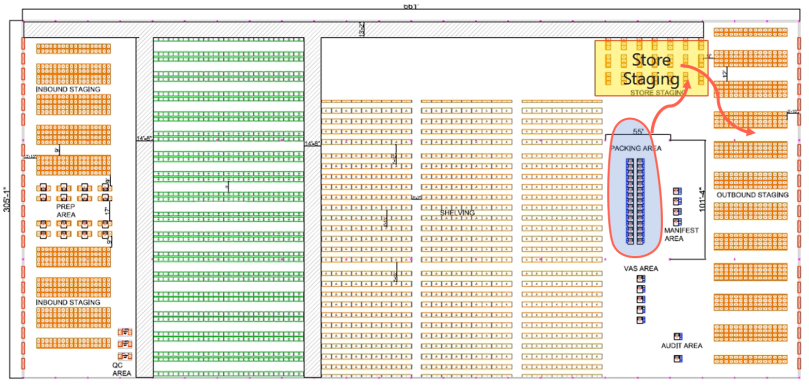

Receiving Locations | Inbound Dock Doors Let us start the discussion about the receiving dock and the inbound dock doors. Retail Warehouses have a wide variety of dock doors, but usually, they’re organized into inbound and outbound doors. When you speak to a Retail Warehouse manager, he or she is going to be very interested in making sure you support the concept of an inbound dock door, because they want to track where the product was received at. So if it’s ever lost, at least they can know where it started from. To do that, they number each of the inbound dock doors. You’ll frequently see the number written on the door itself or just above.  And again, what they’re expecting the system to do is to record, whenever a case is received, somehow the part of the receiving process should note at what dock door was this particular case received. Well, that kind of poses a problem for D365 F&O Warehouse management, because it doesn’t really have the concept of individual dock doors. It really has the concept of a giant dock door. So all of this product you see here that’s been located in front of these dock doors would all appear to be in the same location within D365 F&O, and you’ll have to set this up as RECV or we say Receiving location/zone.  But this is fine because there is a way that we can capture where a given product was maybe not necessarily received, but it was palletized shortly thereafter within, a few seconds probably of being received. So we’ll be able to get around that limitation and explain to the warehouse manager how we’ll provide just as much visibility as he has today or he wants using the D365 F&O Warehouse management module. Inbound Staging Locations by Destination  Now let us look at Staging locations at the Inbound side. One of the distinguishing characteristics of Retail Warehouses is that when products come in at a receiving door, it gets sorted based on all these different destinations that the product may travel to. Some of it will go back to be put-away, but a lot of it may go through other processes and processing areas before it’s really ready for sale. And as a result, when a product comes immediately from the receiving door, it needs to be sorted on to pallets that are designated at that door to go to a particular area.  And each of those staging locations there at a given door will have a corresponding location code that indicates not only where that product is going but also what dock door it’s being received at. And so in that way, we can get around this limitation that D365 F&O only has one giant dock door that product seems to be received within. You then move it to these staging locations and you’ll immediately know and have some history of where that particular case was received. If you think about the receiving dock, it’s really a series of dock doors in a Retail Warehouse with some area right behind those dock doors. Well, if we zoom into those dock doors it will look something like this.  There you can start to see those pallets that are associated with a specific destination. A warehouse worker near the Unloading area who is responsible for processing the goods of the truck through the receiving process. As the warehouse worker process the goods, there will be a series of folks inside of the trailer that will be unloading it. There you can start to see those pallets that are associated with a specific destination. A warehouse worker near the Unloading area who is responsible for processing the goods of the truck through the receiving process. As the warehouse worker process the goods, there will be a series of folks inside of the trailer that will be unloading it. They’ll be throwing it on to a little conveyor that runs to someone very close nearby, maybe only 20, 30 feet away that will receive the cartons into the system.  They’ll flow from there to another warehouse worker, who will palletize it on a pallet that’s going to the destination that that carton needs to move to, and they will be scanning it on to that pallet so that we’ll know exactly where it needed to go and, also, what dock door it was received at. Because, you know, at dock number one, there will be a QC pallet location number one. But at dock number two, there will be a QC pallet number two. So that’s, in turn, how they can determine whether or not it was received at dock door one or dock door two.  Store Staging Location For the brick and mortar side of the business, the Retail Warehouse manager is going to expect that there’s some area in which he can stage the products that are going to specific stores a couple of days in advance of when they actually have to ship. This is usually called the Store Staging area. And if you look at the CAD layout, it is the area shaded in yellow.  Now, what’s going to happen is as cartons or items are picked, they’re going to be taken to a packing station, packed out, and then moved to the storage — the store staging area. There should be, a couple of pallets for every store. And then, once those pallets are full and it’s about time to start shipping a given store, they’ll be moved down to the outbound staging location in front of the door where that store intends to load. Shipping Staging Locations Let us look at the Staging locations on the outbound dock. But before that let us discuss how retailers ship to their brick and mortar stores. Typically, the most active time in a retail store is naturally the weekend. That’s when they sell through a lot of their product. So the replenishments need to get out starting on that Monday and get into the stores by at least Friday because they want to have most of the stock on hand for the biggest days of the week in every store, which is the weekend. So if you have 50 stores and there are five days to ship before the weekend, you will typically ship, ten of those stores on every day. And so what that means is that store staging area today is being used to accumulate the product that will ship out tomorrow. So that raises the question of, where are we going to stage the stuff that’s shipping out today to the stores? Well, that’s going to be in the shipping staging lanes or shipping staging locations that are behind each dock door, and you can see them here in the shaded region in yellow.  Let us take a look at the picture below of the Shipping staging location to understand what we’re trying to do. But what the Retail Warehouse manager needs is an area behind each dock door that has been labeled, and you can see on the right-hand photo which is what you see above the staging lanes. They actually are bar codes or check digits, and they can usually be scanned with a long-range scanner that’s on a mobile device so that you can pull a pallet and stage it behind a given dock door, you can scan the staging aisle where you put it, and the system will track where it is.  This is something that the Retail Warehouse manager is expecting to be set up and available to him so that he can track the product that has arrived and is ready to load separately from that product that is being picked and staged to load tomorrow, which, in turn, gets stored in the store staging area. So there’s a difference between the store staging area and the shipping staging area. There should be a staging area or staging locations behind each dock door. There is more about the outbound dock. Retail Warehouse managers are very much interested in tracking where a particular carton gets loaded, just to make sure it gets loaded on the right truck. As you can see in this photo below, the outbound dock can get convoluted, and things can happen that you don’t want to happen. A particular pallet, potentially, or the case could get loaded on the wrong truck if you’re not careful.  So to prevent that from occurring, the Retail Warehouse managers will usually label every dock door, and then they will require that when something gets loaded, the person that’s loading it needs to scan a bar code or enter a check digit, as you see here in this photo on the right, to confirm that they are putting the product on the right truck.  Well, this poses a little bit of a snag for D365 F&O because, like the situation in receiving, D365 F&O Warehouse management doesn’t really support the concept of an outbound dock door. The system really assumes that this whole area is one giant dock door called BAYDOOR.  And so that’s just something you need to keep in mind when you’re speaking to a Retail Warehouse manager or putting together an implementation plan, that you’re going to need some other mechanism to ensure that the product gets loaded on to the proper truck. And here we finish our journey through different Staging locations. I hope this blog was successful in providing a proper visualization of a different Staging Locations in a Retail Warehouse so you can talk about during any D365 for Commerce implementation utilizing Advance Warehouse management. In our next blog, we are going to zoom into the detail about yet another complex part of the Warehouse management blueprint hierarchy that is different storage locations, that you should expect to see and need to set up or at least be able to talk inside of a Retail Warehouse. Feel free to reach out for any clarifications. If you like my blog posts then comment and subscribe to the blogs. Please follow me on Facebook | Google+ | Twitter | Skype (sumit0417) #RetailDAXing #D365Commerce Disclaimer: The information in the weblog is provided “AS IS”; with no warranties, and confers no rights. All blog entries and editorial comments are the opinions of the author. Credits: Microsoft Learn, Microsoft Docs Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

__________________

Расскажите о новых и интересных блогах по Microsoft Dynamics, напишите личное сообщение администратору. |

|

|

|

|

|